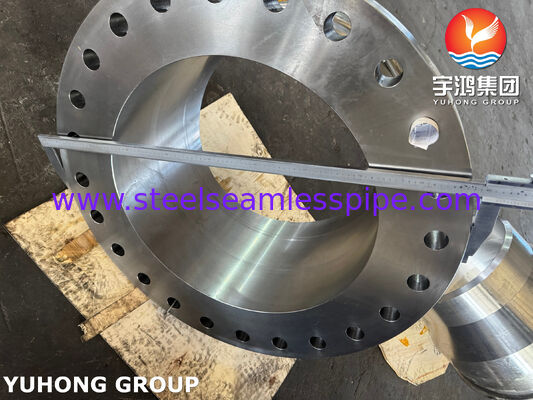

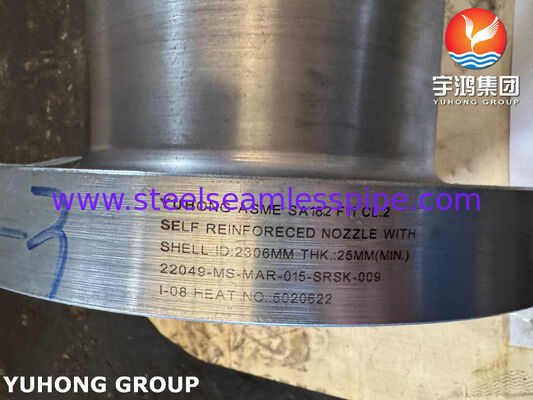

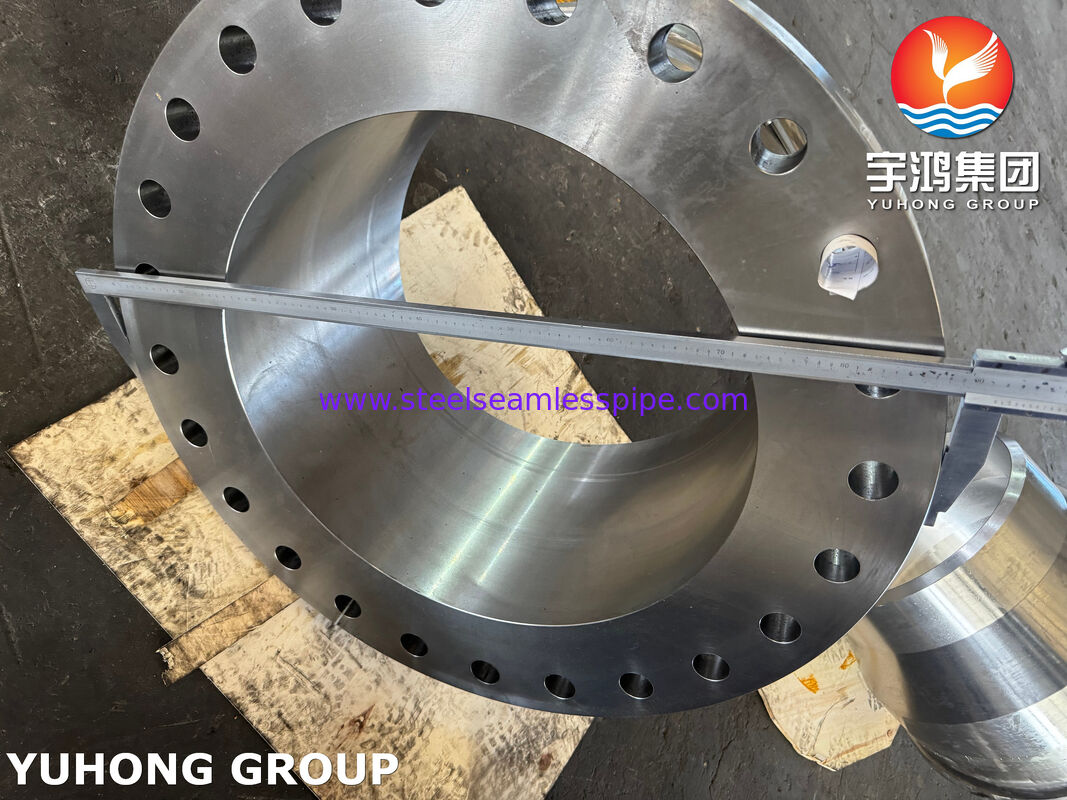

ASME SA182 F11 Cl.2 Self Reinforced Nozzle For Pressure Vessel

The ASME SA182 F11 Cl.2 self-reinforcing nozzle represents a high standard configuration for pressure vessel nozzles: it is integrally forged from chromium-molybdenum alloy steel (1.25Cr-0.5Mo) suitable for medium- and high-temperature environments.

It is primarily used in critical and demanding equipment with extremely high safety requirements, such as hydrogenation reactors and high-temperature, high-pressure heat exchangers.

Properties of Material SA182 F11 Cl.2

This material was chosen to match the self-reinforcing design, as it is commonly used in harsh environments:

Medium- and High-Temperature Performance: It exhibits good creep strength and oxidation resistance below approximately 550°C, making it ideal for high-temperature pressure vessels in oil refining, chemical, and power plants.

Weldability: As a low-alloy steel, its weldability is acceptable, but strict preheating and post-weld heat treatment are required to eliminate welding stress, prevent cold cracking, and restore the properties of the heat-affected zone.

Heat Treatment: Normalizing and tempering of "Cl.2" provides a balanced strength, toughness, and microstructure stability.

Chemical Composition

| Element |

Composition, w.t % Grades |

| LF1 |

LF2 |

LF3 |

LF5 |

LF6 |

LF9 |

LF787 |

| Carbon max |

0.30 |

0.30 |

0.20 |

0.30 |

0.22 |

0.20 |

0.07 |

| Manganese |

0.60-1.35 |

0.60-1.35 |

0.90 max |

0.60-1.35 |

1.15-1.50 |

0.40-1.06 |

0.40-0.70 |

| Phosphorus max |

0.035 |

0.035 |

0.035 |

0.035 |

0.025 |

0.035 |

0.025 |

| Sulfur max |

0.040 |

0.040 |

0.040 |

0.040 |

0.025 |

0.040 |

0.025 |

| Silicon(a) |

0.15-0.30 |

0.15-0.30 |

0.20-0.35 |

0.20-0.35 |

0.15-0.30 |

... |

0.40 max |

| Nickel |

0.40 max(b) |

0.40 max(b) |

3.30-3.70 max |

1.00-2.00 max |

0.40 max(b) |

1.60-2.24 |

0.70-1.00 |

| Chromium |

0.30 max(b)(c) |

0.30 max(b)(c) |

0.30 max(c) |

0.30 max(c) |

0.30 max(b)(c) |

0.30 max(c) |

0.60-0.90 |

| Molybdenum |

0.12 max(b)(c) |

0.12 max(b)(c) |

0.12 max(c) |

0.12 max(c) |

0.12 max(b)(c) |

0.12 max(c) |

0.15-0.25 |

| Copper |

0.40 max(b) |

0.40 max(b) |

0.40 max |

0.40 max |

0.40 max(b) |

0.75-1.25 |

1.00-1.30 |

| Niobium(e) |

0.02 max(d) |

0.02 max(d) |

0.02 max |

0.02 max |

0.02 max |

0.02 max |

-0.02 min |

| Vanadium |

0.08 max |

0.08 max |

0.03 max |

0.03 max |

0.04-0.11 |

0.03 max |

0.03 max |

| Nitrogen |

... |

... |

... |

... |

0.01-0.030 |

... |

... |

Mechanical Requirements

Grade

Class |

Tensile

Strength |

Yield

Strength

min |

Elongation

min |

Hardness

max |

| ksi |

MPa |

ksi |

MPa |

% |

HBW |

LF1

CL1 |

60-85 |

415-585 |

30 |

205 |

25 |

197 |

LF2

CL1 |

70-95 |

485-655 |

36 |

250 |

22 |

197 |

LF2

CL2 |

70-95 |

485-655 |

36 |

250 |

22 |

197 |

LF3

CL1 |

70-95 |

485-655 |

37.5 |

260 |

22 |

197 |

LF3

CL2 |

70-95 |

485-655 |

37.5 |

260 |

22 |

197 |

LF5

CL1 |

60-85 |

415-585 |

30 |

205 |

25 |

197 |

LF5

CL2 |

70-95 |

485-655 |

37.5 |

260 |

22 |

197 |

LF6

CL1 |

66-91 |

455-630 |

52 |

360 |

22 |

197 |

LF6

CL2 |

75-100 |

515-690 |

60 |

415 |

20 |

197 |

LF6

CL3 |

75-100 |

515-690 |

60 |

415 |

20 |

197 |

| LF9 |

63-88 |

435-605 |

46 |

315 |

25 |

197 |

LF787

CL2 |

65-85 |

450-585 |

55 |

380 |

20 |

197 |

LF787

CL3 |

75-95 |

515-655 |

65 |

450 |

20 |

197 |

Charpy V-Notch Impact Properties

| Charpy V-Notch Energy Requirements for 10x10 mm Specimens |

Grade

Class |

A |

B |

| ft·lbf |

J |

ft·lbf |

J |

LF1

LF9 |

13 |

18 |

10 |

14 |

LF2

CL1 |

15 |

20 |

12 |

16 |

LF3

CL1 |

15 |

20 |

12 |

16 |

LF5

CL1

CL2 |

15 |

20 |

12 |

16 |

LF787

CL2

CL3 |

15 |

20 |

12 |

16 |

LF6

CL1 |

15 |

20 |

12 |

16 |

LF2

CL2 |

20 |

27 |

15 |

20 |

LF3

CL2 |

20 |

27 |

15 |

20 |

LF6

CL2

CL3 |

20 |

27 |

15 |

20 |

Frequently used ASTM Grades

| Material |

Pipes |

Fittings |

Flanges |

Valves |

Bolts & Nuts |

| Carbon Steel |

A106 Gr A |

A234 Gr WPA |

A105 |

A216 Gr WCB |

A193 Gr B7

A194 Gr 2H |

| A106 Gr B |

A234 Gr WPB |

A105 |

A216 Gr WCB |

| A106 Gr C |

A234 Gr WPC |

A105 |

A216 Gr WCB |

| |

Carbon Steel

Alloy

High-Temp |

A335 Gr P1 |

A234 Gr WP1 |

A182 Gr F1 |

A217 Gr WC1 |

A193 Gr B7

A194 Gr 2H |

| A335 Gr P11 |

A234 Gr WP11 |

A182 Gr F11 |

A217 Gr WC6 |

| A335 Gr P12 |

A234 Gr WP12 |

A182 Gr F12 |

A217 Gr WC6 |

| A335 Gr P22 |

A234 Gr WP22 |

A182 Gr F22 |

A217 Gr WC9 |

| A335 Gr P5 |

A234 Gr WP5 |

A182 Gr F5 |

A217 Gr C5 |

| A335 Gr P9 |

A234 Gr WP9 |

A182 Gr F9 |

A217 Gr C12 |

| |

Carbon Steel

Alloy

Low-Temp |

A333 Gr 6 |

A420 Gr WPL6 |

A350 Gr LF2 |

A352 Gr LCB |

A320 Gr L7

A194 Gr 7 |

| A333 Gr 3 |

A420 Gr WPL3 |

A350 Gr LF3 |

A352 Gr LC3 |

| |

Austenitic

Stainless

Steel |

A312 Gr TP304 |

A403 Gr WP304 |

A182 Gr F304 |

A182 Gr F304 |

A193 Gr B8

A194 Gr 8 |

| A312 Gr TP316 |

A403 Gr WP316 |

A182 Gr F316 |

A182 Gr F316 |

| A312 Gr TP321 |

A403 Gr WP321 |

A182 Gr F321 |

A182 Gr F321 |

| A312 Gr TP347 |

A403 Gr WP347 |

A182 Gr F347 |

A182 Gr F347 |

Application:

Petrochemical and Refining:

Equipment such as hydrogenation reactors, hydrodesulfurization units, high-pressure separators, and high-temperature heat exchangers operate under high temperature, high pressure, and hydrogen-rich environments for extended periods, requiring materials with resistance to hydrogen corrosion and creep.

Energy and Power:

High-pressure boilers, steam headers, and components subjected to high-temperature steam in thermal power plants, as well as in supercritical or ultra-supercritical units.

Chemical Processes:

Critical connection points such as high-pressure synthesis towers and high-temperature reactors in ammonia and methanol synthesis plants.

Other Harsh Operating Conditions: Applications involving severe thermal cycling, fatigue loads, or requiring extremely high structural integrity.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!