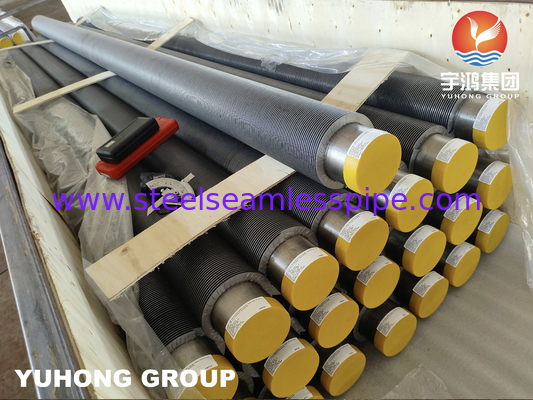

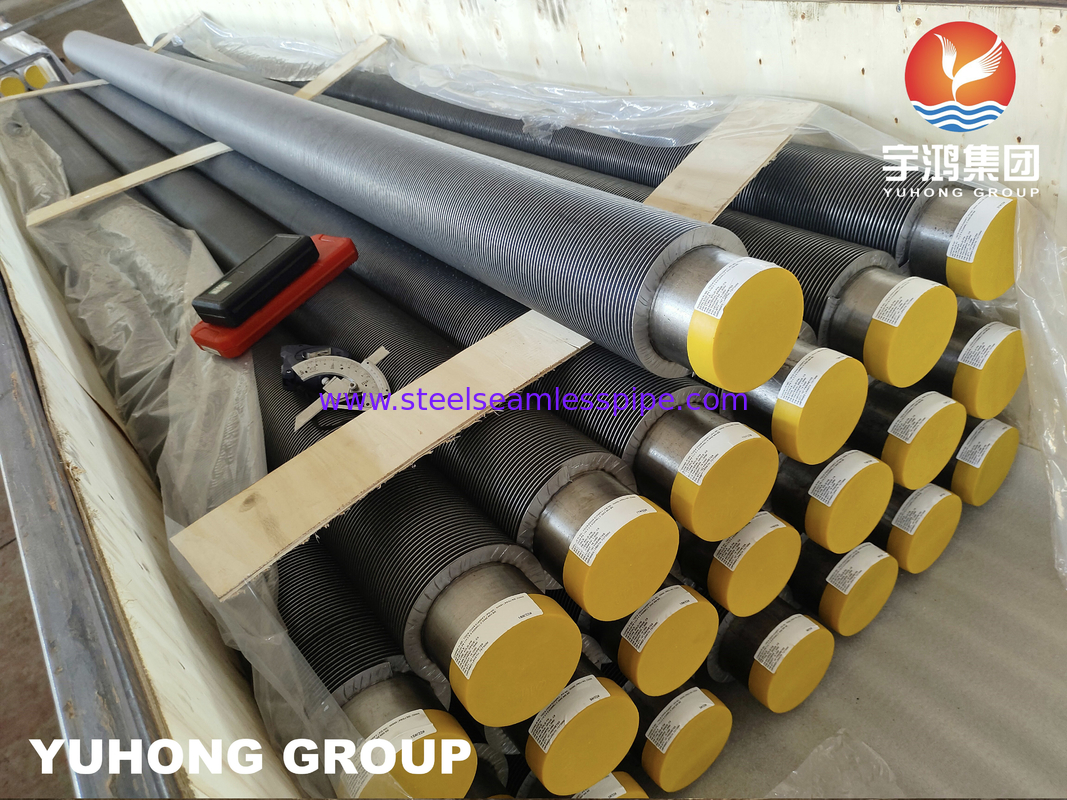

Tube à ailettes soudées haute fréquence TP347H, haute température et résistance à la corrosion, applicable aux chaudières utilitaires

Tube à ailettes soudées haute fréquence en acier inoxydable TP347H —— Haute température et efficacité, résistance à la corrosion et durabilité, solution d'échange thermique

1. Aperçu du produit

Le tube à ailettes soudées haute fréquence en acier inoxydable YUHONG TP347H adopte l'acier inoxydable austénitique stabilisé au niobium (TP347H/06Cr18Ni11Nb) comme tube de base, et forme une liaison métallurgique entre les ailettes et le tube de base grâce à une technologie de soudage par résistance haute fréquence avancée. Le produit combine une excellente résistance à haute température, une résistance à l'oxydation et à la corrosion, conçu spécifiquement pour les exigences d'échange thermique efficaces dans des conditions de travail extrêmes. C'est un composant de transfert de chaleur idéal dans les domaines des chaudières, des produits chimiques et des centrales électriques.

2. Avantages clés

- Excellentes performances des matériaux

Stabilité à haute température : La température maximale de résistance à l'oxydation peut atteindre 850 ℃, et la température de fonctionnement des composants supportant la pression peut atteindre 650 ℃. Il possède une excellente résistance au fluage pendant le service à long terme.

Forte résistance à la corrosion : Il présente d'excellentes performances dans les milieux acides, alcalins, salins et l'eau de mer, et sa résistance à la corrosion intergranulaire a été testée selon les normes internationales (telles que la méthode HNO3 à 65%).

Fiabilité du soudage : L'ajout d'élément niobium (Nb ≥ 10 × C%) pour supprimer les fissures à chaud et assurer une jointure de soudure ferme entre les ailettes et les tubes de base, adapté aux procédés de soudage haute fréquence.

- Technologie de processus avancée

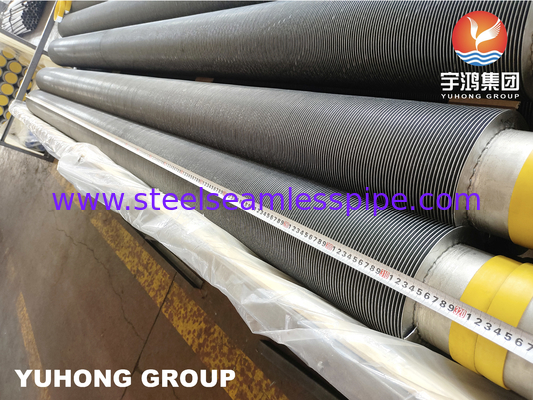

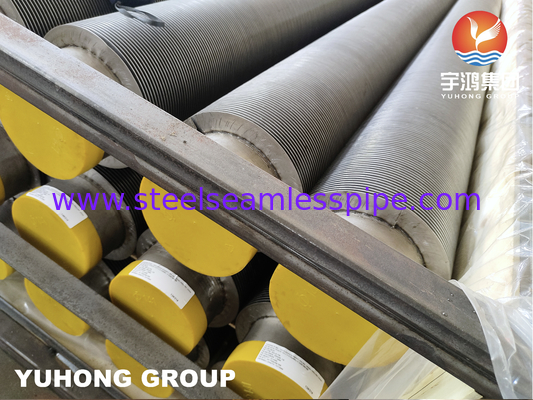

Technologie de soudage par résistance haute fréquence : réalise un soudage de précision entièrement automatique des ailettes et des tubes de base, avec une résistance de liaison élevée, une faible résistance thermique et une efficacité de transfert de chaleur augmentée de plus de 30%.

Traitement thermique strict : Le traitement de solution (refroidissement à l'eau à 1050 ℃~1100 ℃) assure une structure austénitique unique et une taille de grain de 7 ou plus, améliorant la ténacité et la stabilité du matériau.

- Adaptabilité multifonctionnelle

Prise en charge des spécifications personnalisées : Le diamètre extérieur du tube à ailettes couvre Φ 22mm~273mm, et l'épaisseur de paroi est de 1mm~40mm, répondant aux exigences de disposition de divers échangeurs de chaleur.

Compatible avec les environnements de milieux complexes : convient aux scénarios tels que la récupération de chaleur résiduelle des gaz de combustion, l'échange de chaleur des gaz corrosifs et la production de vapeur à haute température.

3. Domaines d'application typiques

| Industrie |

Scénarios d'application |

Points d'alignement des performances |

| Chaudières industrielles |

Surchauffeurs et resurchauffeurs haute température d'unités supercritiques |

Résiste à la vapeur haute pression à 650°C, résiste à l'oxydation et à l'amincissement des parois |

| Pétrochimie |

Échangeurs de chaleur de fours de craquage, cristalliseurs |

Résiste à la corrosion par HCl, empêche la carburation à haute température |

| Énergie verte |

Unités de récupération de chaleur résiduelle des gaz de combustion, préchauffeurs d'air |

Tolère la corrosion au point de rosée acide, prolonge la durée de vie |

| Aérospatiale |

Composants de gestion thermique du système d'échappement du moteur |

Maintient une résistance à l'oxydation stable |

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!